- ZNAL20-1

- China

- 15-20 days

- 20mt/m

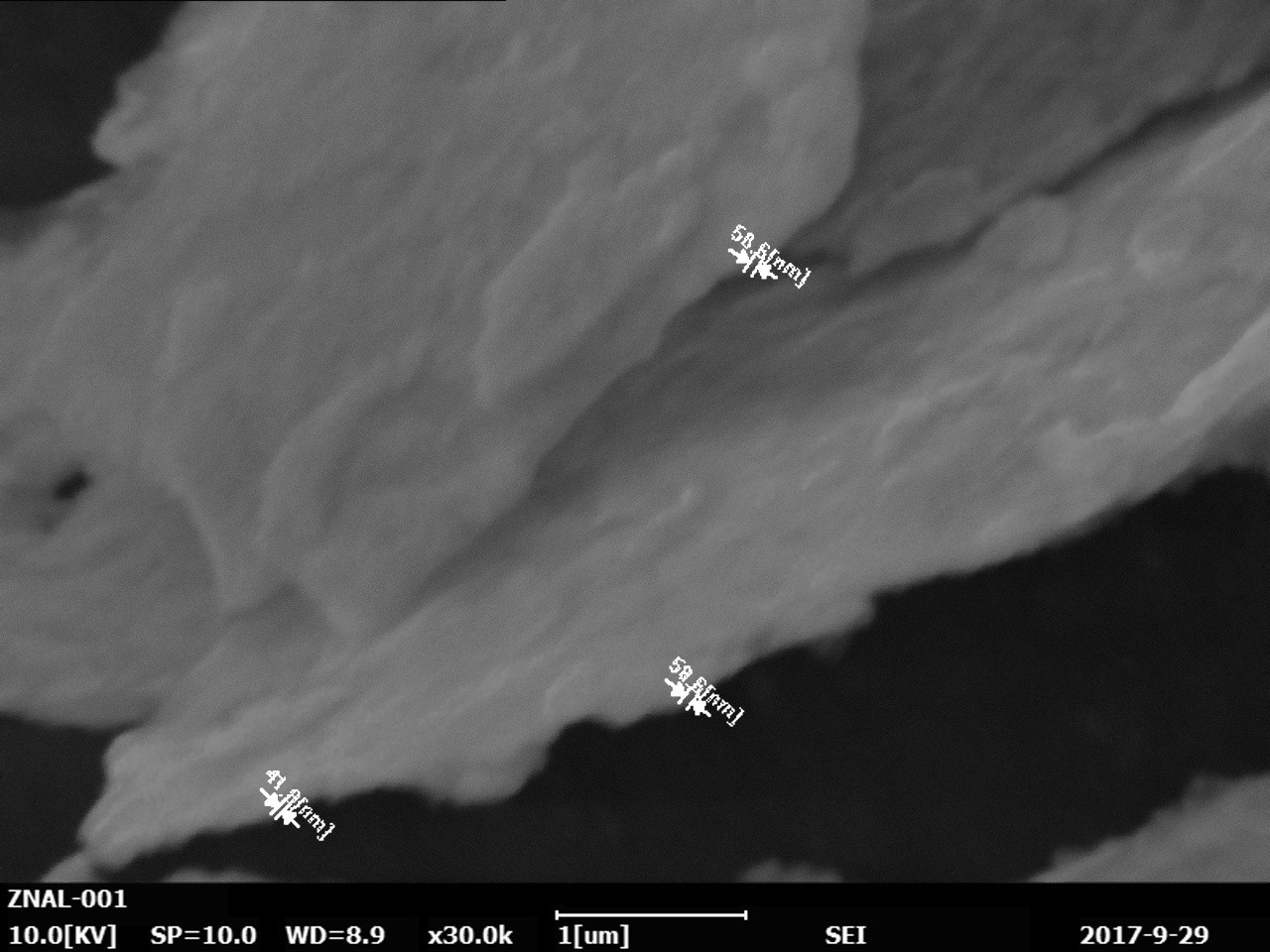

1. Particle size as D50 about 13-15um;

2. Zinc and alloy content ratio as 80/20;

3. Advantages: Nanofabrication, multi-coated layer processing, slower sedimentation, longer salt fog time, better dispersibility, better shielding/protection effectiveness,

Flake Aluminum Alloy Powder

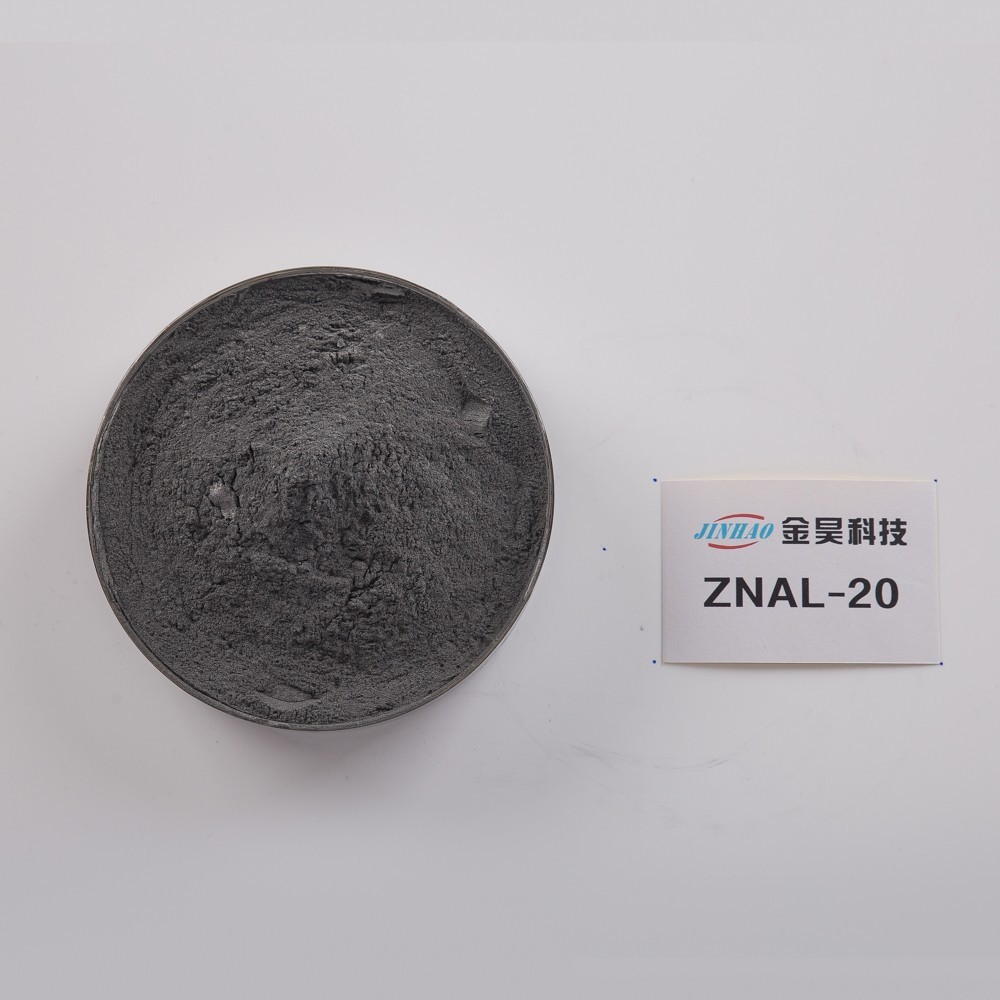

Produce name: Flake Zn-Al Alloy Powder

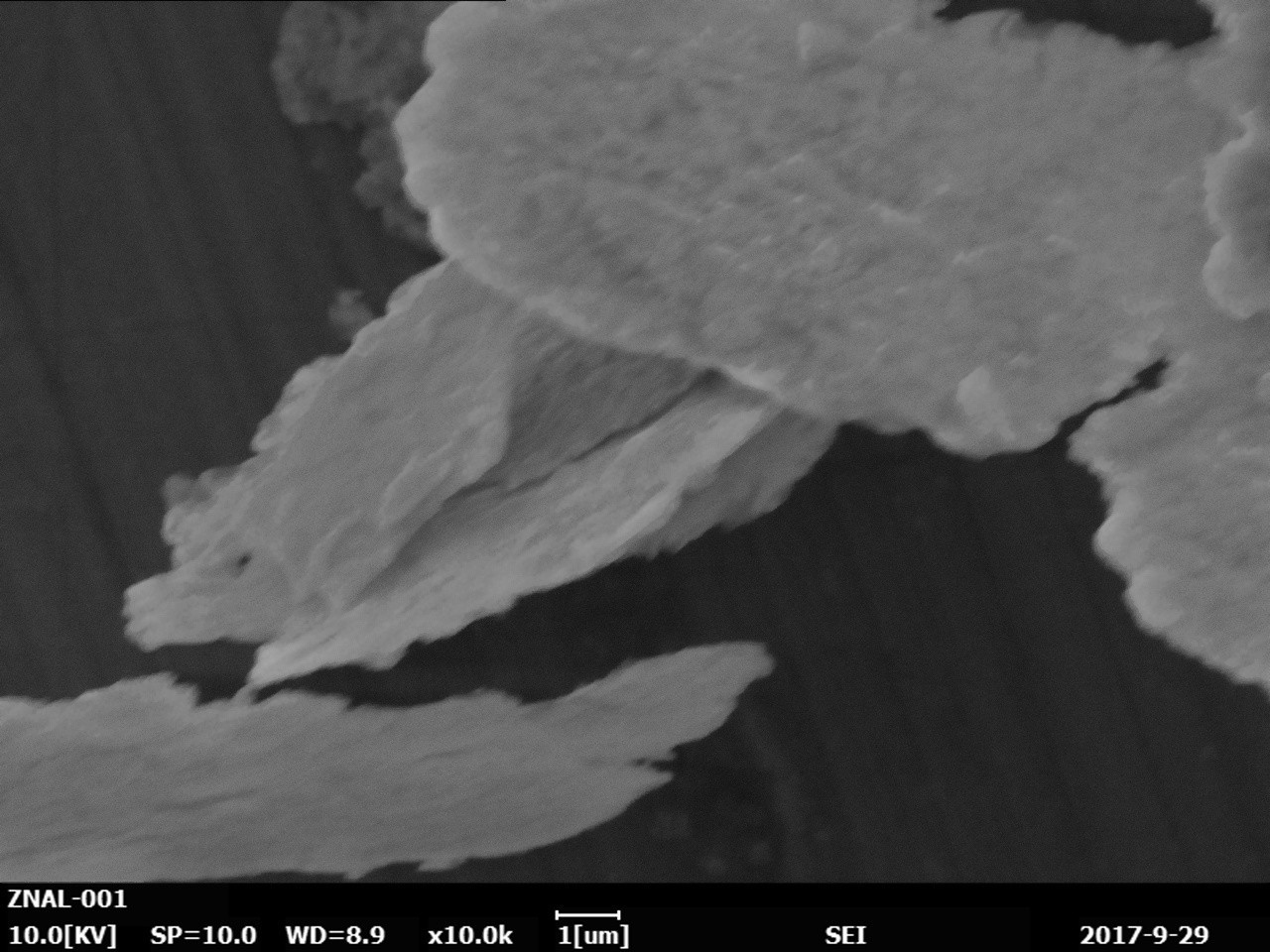

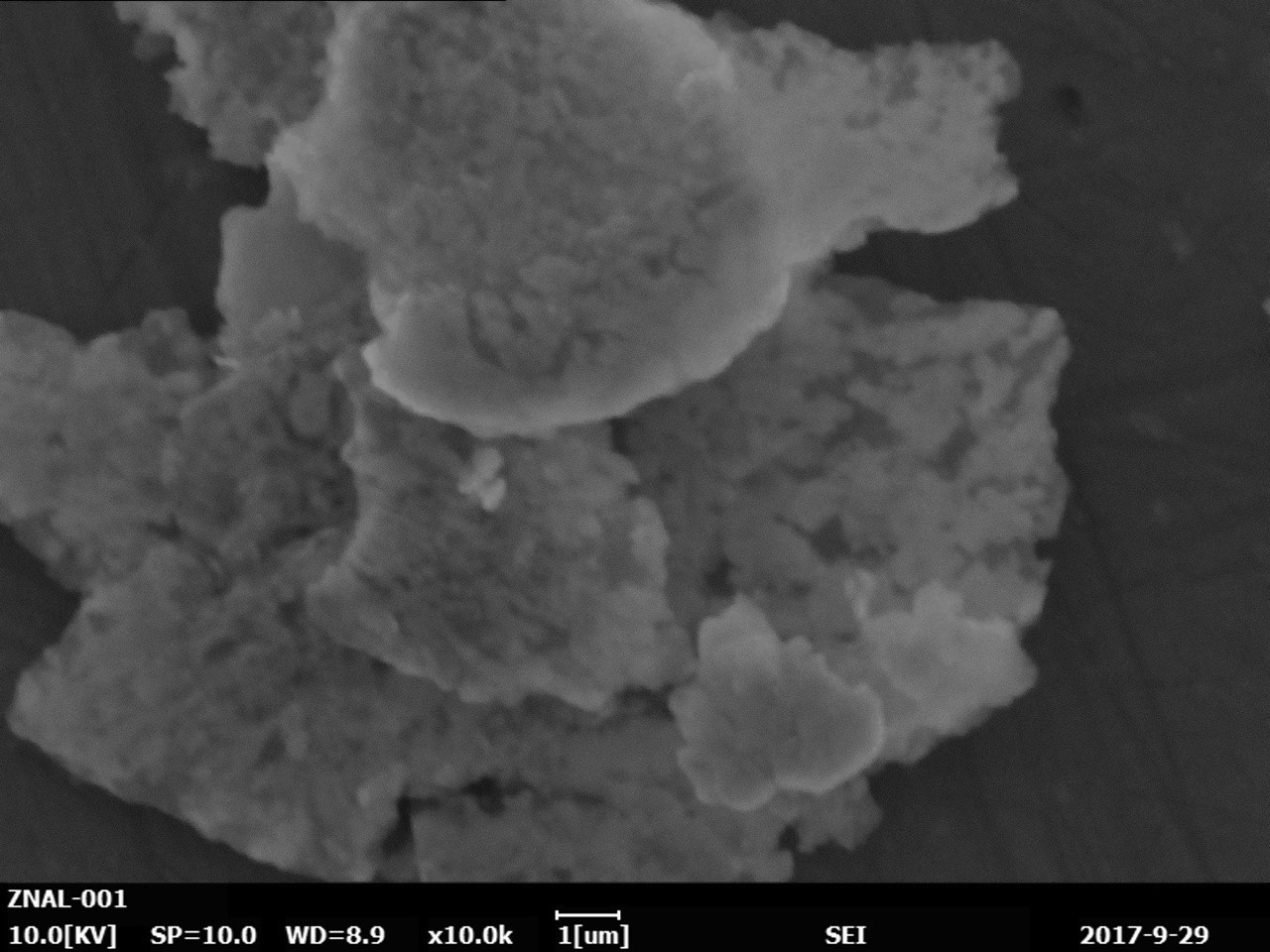

Appearance: Lamellar shape

Advantages: Nanofabrication, multi-coated layer processing, slower sedimentation, longer salt fog time, better dispersibility, better shielding/protection effectiveness,

Application: Mainly used in Dacrome /Geomet coating industry, widely used in organic and water based painting, powder coating and painting for ships and warships, automotive parts, vehicles, rail carriage, electricity infrastructure, steel structure building materials and the like surface treatment.

Chemical property and features:

1. The flake alloy powder has both of advantages of the zinc flake powder and aluminum flake powder, making it show the equilibrium performance in the material producing, anti-corrosion and coating appearance features.

2. The flake Zn-Al alloy powder has better ductility, easily controlled flakes’ size, higher specific surface area; it has not only the anodic protective effectiveness as the pure zinc layer protecting the basic steel matrix, but also has adequate aluminum to make it form into the integrated aluminum oxide(Al2O3) protecting film to improve the anti-corrosion performance.

3. With the aluminum’s nature, the flake alloy powder has the beautiful metallic shining appearance that the zinc powder does not have. Considering to the different density of the zinc powder and aluminum powder when in mixing as the coating material, the problem of the coating liquid inhomogeneity can be easily solved from replacing by the flake Zn-Al alloy powder, which making it as the perfect anti-corrosion pigment material for the free of Chromium(Cr) Dacromet coating.

Flake Zn-Al Alloy Powder:

Grade

| Average Particle Size D50(um) | Flake Thickness (um) | Water Covering (min cm²/g±10%) | Bulk Density (g/cm3) | Packaging (KG) |

ZNAL20-1 | 13-15 | 0.05-0.12 | ≥10000 | 0.50 | 50/25 |

ZNAL20-2 | 5-7 | 0.02-0.10 | ≥15000 | 0.50 | 50/25 |