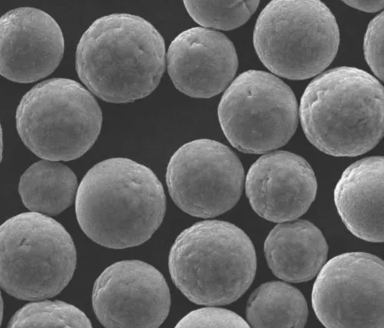

1.Better sphericity and flowability

2.High purity,lower oxyen content,lower rate of hollow powder

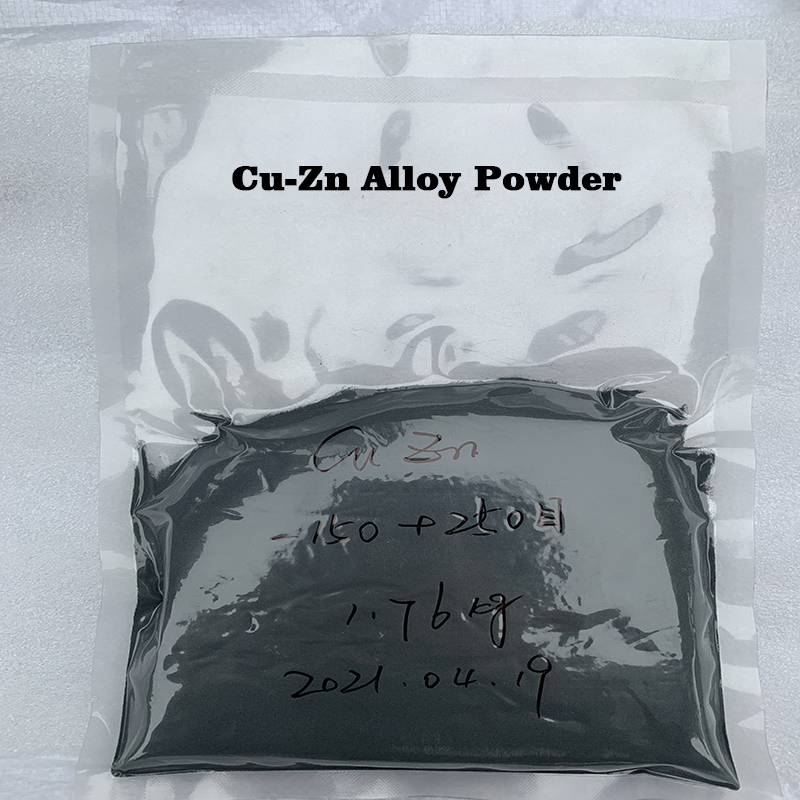

3.The different copper alloy powder can be customized with different particle size

4.Sample is available

Copper Alloy Powder

Copper Alloy Powder

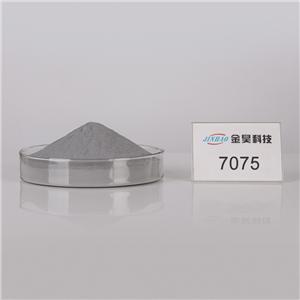

Products: CuCrZr and T2

Technology: Vacuum Induction Melting Gas Atomization (VIGA)

Advantages: The AM parts have better thermal and electrical conductivity, with the designing flexibility, other products with complex inner structure and cooling tunnels can be easily made.

Application: AM aerospace engine thrust chamber and components or mould with better cooling effect.

Particle Size: 14-45um,15-53um,20-63um,63-106um or customized etc.

Packaging:Aluminum foil bag/Plastic bottle/Steel barrel/ or Vacuum packing.

Please feel free to contact with us for other customized Cu-alloy powders.

产品性能 Product Performance | ||

材料Nmae | 硬度(HV) | 导电率Conductivity (ms/s) |

T2 | 70-110 | 56 |

CuCrZr | 110-145 | 43 |